Tranmission/

drivetrain Basics

Transmissio/

Drivetrain Basics

The transmission and drivetrain of a BMW are crucial systems that deliver power from the engine to the wheels, enabling movement and control. These components are designed to handle the performance demands of BMW’s engines while providing smooth power delivery, precise handling, and a dynamic driving experience. Proper functioning of each component is essential for performance, efficiency, and reliability.

Transmission

The transmission, or gearbox, is responsible for regulating engine power and torque delivered to the wheels. BMW offers a variety of transmission options:

Why It’s Important: A well-functioning transmission ensures optimal engine performance, fuel efficiency, and driver comfort.

Common Issues: Symptoms of a failing transmission include hard shifts, slipping gears, delayed engagement, and warning lights.

Fluid Maintenance

- Change transmission fluid every 30,000–60,000 miles, depending on the transmission type and driving conditions. Neglecting fluid changes can lead to overheating and increased wear.

- Always use BMW-approved transmission fluid to ensure compatibility.

Monitor for Symptoms

Watch for warning signs like slipping gears, delayed shifts, or a transmission warning light. Address these issues promptly.

Software Updates

For automatic and DCT systems, ensure the Transmission Control Unit (TCU) software is up-to-date to maintain optimal shifting performance.

Automatic

- Automatic Transmission (ZF or GM): Smooth and precise shifting, often featuring advanced adaptive controls that adjust shift patterns based on driving style.

Manual

- Manual Transmissions offer a driver-focused option that allows full control over gear selection, preferred by enthusiasts.

DCT

- Dual-Clutch Transmission (DCT) Combines the speed of a manual with the convenience of an automatic, delivering lightning-fast shifts for high-performance models.

Clutch

In manual and dual-clutch systems, the clutch connects and disconnects the engine from the transmission, allowing smooth gear changes and power transfer.

- Why It’s Important: The clutch ensures smooth engagement and disengagement of power during shifting or when idling.

- Common Issues: Worn clutch plates can cause slipping, difficulty in engaging gears, or a burning smell.

Monitor Wear

Watch for signs of clutch wear, such as slipping, difficulty engaging gears, or a burning smell during acceleration.

Replacement

Replace the clutch every 80,000–100,000 miles, or sooner depending on driving habits.

Driving Habits

Avoid riding the clutch (keeping partial pressure on the pedal) and unnecessary high-rev launches, as these accelerate wear.

Inspect Clutch Hydraulics

Check the clutch master cylinder and slave cylinder for leaks or reduced pressure.

Torque Converter

The torque converter is a critical component of automatic transmissions. It uses hydraulic fluid to transfer power from the engine to the transmission while multiplying torque during acceleration.

- Why It’s Important: It allows the engine to remain running while the vehicle is stationary and provides smooth acceleration.

- Common Issues: Torque converter failure can result in shuddering, slipping, or overheating.

Fluid Care

Regularly change transmission fluid, as it is critical for the lubrication and operation of the torque converter.

Monitor for Symptoms

Look for shuddering, slipping gears, or hesitation during acceleration, which may indicate torque converter issues.

Prompt Repairs

If problems persist, inspect and replace the torque converter to prevent damage to the transmission.

Driveshaft

The driveshaft transmits power from the transmission to the differential. In BMW rear-wheel-drive (RWD) vehicles, it connects the rear differential to the gearbox, while in xDrive models, it also includes a front driveshaft.

- Why It’s Important: The driveshaft ensures efficient power transfer to the wheels for smooth acceleration.

- Common Issues: Worn universal joints (u-joints) or a damaged center support bearing can cause vibrations and clunking noises.

Inspect Regularly

- Check for vibrations, clunking sounds, or visible damage to the driveshaft.

- Inspect universal joints (u-joints) and the center support bearing for wear or play.

Lubrication

If applicable, ensure that u-joints are properly lubricated to avoid premature wear.

Replacement

Replace the driveshaft or its components if vibrations or noises persist, as these could damage the transmission or differential.

Differential

The differential splits power from the driveshaft to the wheels, allowing them to rotate at different speeds, which is essential during cornering. BMW vehicles feature either an open differential(standard) or a limited-slip differential (LSD) for enhanced traction.

- Why It’s Important: A properly functioning differential improves handling, traction, and stability, particularly in performance driving or adverse weather.

- Common Issues: Whining noises, leaks, or difficulty in cornering may indicate differential problems.

Fluid Maintenance

Change the differential fluid every 30,000–60,000 miles. Use the correct BMW-approved gear oil for your specific differential type.

Check for Leaks

Inspect the differential housing for signs of oil leaks. Replace the gasket or seals as needed.

Monitor for Noise

Listen for whining, grinding, or other unusual noises when accelerating or cornering, which may indicate internal wear or damage.

Upgrade Considerations

If you drive aggressively or track your vehicle, consider upgrading to a limited-slip differential (LSD) for better traction and handling.

Transfer Case

In all-wheel-drive BMWs (xDrive), the transfer case is responsible for distributing power between the front and rear wheels. It ensures traction and stability by dynamically adjusting power distribution based on driving conditions.

- Why It’s Important: The transfer case provides seamless power delivery and improved traction in slippery or uneven conditions.

- Common Issues: Symptoms of transfer case failure include grinding noises, erratic power distribution, and driveline vibrations.

Fluid Changes

Replace the transfer case fluid every 50,000 miles to maintain proper lubrication and performance.

Calibrations

Recalibrate the transfer case after fluid changes or repairs to ensure proper power distribution.

Monitor Symptoms

Look for grinding noises, vibrations, or erratic power distribution between the front and rear wheels. These may indicate internal wear or actuator issues.

Address Warning Lights

If the xDrive system malfunction light appears, have the transfer case and related components inspected immediately.

Axles and CV Joints

The axles transfer power from the differential to the wheels, while constant velocity (CV) jointsallow the axles to maintain power delivery while the wheels turn and move.

- Why It’s Important: Axles and CV joints ensure uninterrupted power delivery, even during sharp turns or suspension movement.

- Common Issues: Clicking or popping noises during turns may indicate worn CV joints, while a broken axle can result in total power loss to a wheel.

Inspect CV Boots

Regularly check CV boots for tears, cracks, or grease leaks. Damaged boots expose the CV joint to dirt and moisture, causing premature wear.

Listen for Noises

Clicking or popping sounds when turning indicate worn CV joints. Replace them promptly to avoid axle failure.

Replacement Timing

Replace axles and CV joints if there are signs of wear or damage. Waiting too long can lead to complete axle failure and loss of power delivery.

Transmission Control Unit (TCU)

In all-wheel-drive BMWs (xDrive), the transfer case is responsible for distributing power between the front and rear wheels. It ensures traction and stability by dynamically adjusting power distribution based on driving conditions.

- Why It’s Important: The transfer case provides seamless power delivery and improved traction in slippery or uneven conditions.

- Common Issues: Symptoms of transfer case failure include grinding noises, erratic power distribution, and driveline vibrations.

Software Updates

Ensure the TCU firmware is updated during routine service to improve shift patterns and system efficiency.

Diagnose Early

Use diagnostic tools to check for fault codes related to the TCU if there are shifting issues or warning lights.

Proper Adaptations

After repairs or transmission fluid changes, reset the TCU adaptations to recalibrate the transmission’s behavior.

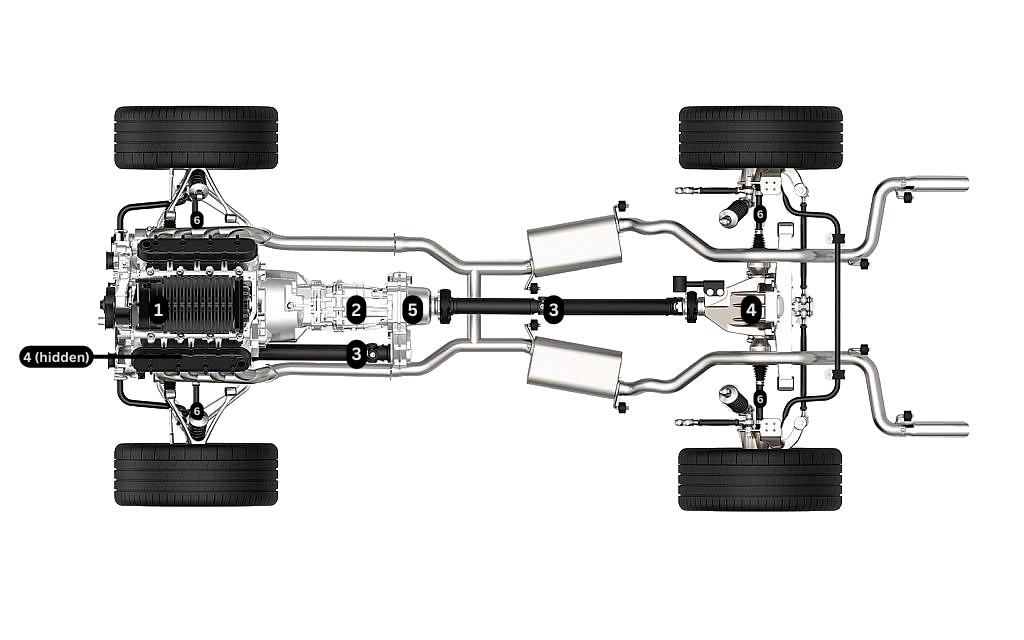

How These Components Work Together

The engine (1) generates power, which is sent to the transmission (2).

The transmission (2) modifies this power by changing gear ratios to suit driving conditions.

The power is then transferred through the driveshaft (3) and split by the differential (4) to the wheels.

In xDrive models, the transfer case (5) ensures balanced power delivery between the front and rear wheels.

The axles and CV joints (6) deliver the power to the wheels, allowing for smooth acceleration, steering, and suspension movement.

Inspection

Regularly inspect the cap for signs of wear or damage, such as cracked rubber seals or corrosion around the edges. Look for signs of coolant leaks around the cap or the expansion tank.

Replacement

Replace the cap every 60,000–90,000 miles or as part of regular cooling system maintenance. A failing cap can lead to more significant issues with pressure loss.

Tip

Always use an OEM or BMW-approved expansion tank cap to ensure proper fit and pressure rating. Avoid over-tightening, as this can damage the seals or the expansion tank itself.

General Maintenance Tips For All Drivetrain Components

Routine Inspections:

- During regular service, have your mechanic inspect the entire drivetrain system, including fluid levels, seals, and mounting points.

Use OEM Parts:

- Always use BMW-approved fluids and parts to ensure compatibility and reliability.

Address Issues Promptly:

- Ignoring drivetrain issues can lead to further damage, increased repair costs, and compromised vehicle safety.